Know Your Fabric

At Made in Banaras, we believe in using only natural fibers, with all our fabrics lovingly handwoven in Banaras and the surrounding regions.

By choosing all-natural materials, our products inherit the timeless quality and luxury that Banaras weaving is known for. This makes our garments not only softer and more breathable, but also more durable than synthetic options.

While Banaras is often associated with the luxurious katan silk, the city’s textile heritage is much more expansive. Our talented weavers are experts in creating a wide range of fabrics and textures. We invite you to discover the full range of their craftsmanship — from the smooth softness of katan to the gleaming beauty of satin, the crisp feel of kora to the breezy lightness of cottons, and the delicate shine of tissues to the earthy charm of tussars.

Katan Silk

Katan silk is the epitome of Banarasi craftsmanship—fine, soft, and delicately lustrous. Made using the highest quality Mulberry Silk in both the warp and weft, Katan silk is woven in a plain weave, lending it exceptional durability and a smooth texture.

Silk Georgette

A popular variation of Katan Silk is Silk Georgette (also known as Silk by Georgette or Summer Silk). This pure silk fabric is created by using twisted silk yarns in the warp or weft, resulting in a lighter, airier fabric—perfect for warmer climates.

Satin Silk

Satin Silk is crafted using the satin weave, a technique that gives the fabric a glossy surface and a soft, luxurious feel. Unlike Katan Silk, Satin has a smooth, almost liquid-like drape and a more vibrant colour payoff due to the dense arrangement of threads. Its luminous sheen makes it a favourite for elegant, statement pieces.

Khaddi Georgette

"Khaddi" refers to handwoven fabric, and Khaddi Georgette is the handloom-woven version of classic Georgette. Made using high-twist silk yarns, this fabric is light, slightly crinkled, and drapes fluidly. It’s often compared to chiffon but has a more structured texture, making it a versatile choice for both casual and formal wear.

Kora Silk

Kora Silk, also known as Banarasi Organza, is an ethereal, sheer fabric woven from un-degummed silk yarns. Because these yarns retain their natural sericin, Kora Silk has a crisp texture, making it lighter and airier than fully processed silk.

Kora Silk Net

A variation of Kora Silk, Kora Net is woven using the net weave technique, where the warp and weft are loosely intertwined, creating an open, airy fabric with a delicate, lattice-like appearance.

Tussar Silk

Also known as Kosa Silk, Tussar Silk is a wild silk variety produced by silkworms that feed on local trees rather than mulberry leaves. This results in a naturally golden-hued fabric with a rich, textured surface. Lightweight and breathable, Tussar Silk is prized for its organic, raw appeal.

Tussar Georgette

A harmonious blend of Tussar Silk and Georgette, this fabric combines the rich texture of Tussar with the fluid drape of Georgette. The interplay of these two silk varieties results in a fabric that is both structured and effortlessly graceful.

Silk & Wool

A testament to Banaras’ evolving craftsmanship, Silk & Wool blends two of the most luxurious fibres—Silk and Pashmina Wool. This handwoven marvel interlaces soft Pashmina in the weft with lustrous Silk in the warp, resulting in a fabric with a satin-like sheen, a smooth yet textured surface, and unparalleled warmth. The twill weave enhances its durability, making it a timeless textile of quiet luxury.

Tissue

Tissue fabric is renowned for its shimmering, gossamer-like appearance. It is created by weaving zari (metallic threads) into the structural weft alongside silk or cotton yarns. The result is a luminous, lightweight fabric that exudes opulence and grace.

Cotton

One of India’s most beloved textiles, cotton from Banaras is distinguished by its softness, breathability, and versatility. Under the expert hands of Banaras’ master weavers, this everyday fabric is elevated through intricate weaving techniques such as Kadhua and Jamdani, producing rich, detailed patterns that celebrate India’s handloom heritage.

Banarasi Textiles: Handcrafted Legacy from Banaras

Kadwa (Kadhua)

The Kadwa technique is one of the most intricate and labour-intensive weaving methods used in Banarasi textiles. Unlike phekwa (cutwork) sarees, where patterns are woven continuously, Kadwa motifs are woven separately, without loose threads at the back—eliminating the need for cutting. This technique allows for multiple motifs of varying sizes, colours, and textures to be incorporated seamlessly into a single fabric. Though more time-consuming, it results in a more durable and visually striking design.

Kadiyal

The Kadiyal technique is a hallmark of skilled handloom artistry, enabling the creation of borders in striking contrast to the body of the fabric. Achieving this contrast requires meticulous dyeing, careful warp setting in different colours, and frequent weft shuttle changes during weaving.

Meenakari

Inspired by the art of enamel work, Meenakari weaving involves the meticulous addition of supplementary coloured resham (silk) threads during the hand-weaving process. This technique introduces vibrant hues into patterns alongside zari, enhancing depth and richness. Meenakari can be executed in both Kadwa and cutwork styles.

Tanchoi

The Tanchoi technique is known for its fine, self-patterned designs achieved through a single or double warp and multiple colored wefts (typically two to five shades). The weave ensures that no floating threads appear on the back of the fabric, resulting in a smooth and intricate all-over design. Tanchoi fabrics are highly valued for their delicate, detailed motifs.

Jangla

One of the oldest weaving styles from Banaras, Janglais recognized for its elaborate floral jaals (net-like patterns) that envelop the entire fabric. When a jaal is woven in a complete Kadwaweave, the pattern is classified as Jangla—a true mark of opulence and skilled craftsmanship.

Jamdani

Originating from Dhaka, Bangladesh, Jamdani weaving is celebrated for its ethereal beauty and fine quality. The technique involves weaving heavier, intricate motifs onto a sheer, lightweight fabric background, creating a striking contrast. Traditionally crafted on pit looms, Jamdani fabrics are synonymous with elegance and artistry.

Jamawar

Jamawar fabrics are characterized by their intricate paisley motifs, meticulously woven into the textile without any loose threads on the reverse side. The result is a seamless, richly detailed fabric that exudes grandeur and sophistication.

Patola

Originally from Patan, Gujarat, Patola textiles are crafted using the double ikat technique, a painstaking resist-dyeing process that results in vibrant, symmetrical patterns. Banarasi weavers, known for their adaptability, have incorporated elements of Patola designs into their repertoire, creating stunning Banarasi Patolas that blend two rich textile traditions.

Paithani

Named after the town of Paithan in Maharashtra, Paithani weaving was historically favoured by royalty. These sarees are distinguished by their rich borders and intricately woven pallus, often featuring motifs inspired by nature and mythology. Zari is woven into the warp, forming a golden base upon which detailed patterns are inlaid using supplementary coloured threads.

From Design to Weave : The Art of Banarasi Handloom

The Design Process

Selecting the Materials

Selecting the Materials

The journey of every Banarasi weave begins with its design - a process that blends tradition with creativity. We are drawn to motifs and patterns that have stood the test of time, ensuring that each textile carries a sense of history while remaining relevant across generations.

Once a design is finalized - either hand-drawn or digitally

The journey of every Banarasi weave begins with its design - a process that blends tradition with creativity. We are drawn to motifs and patterns that have stood the test of time, ensuring that each textile carries a sense of history while remaining relevant across generations.

Once a design is finalized - either hand-drawn or digitally conceptualized - it is meticulously transferred onto a large graph paper, a process known as “Likhai.” This intricate task is carried out by skilled artisans known as Nakshaband, who create precise blueprints that dictate the weaving pattern.

The design is then hand-punched onto Naksha Pattas - cardboard stencils that guide the loom during weaving. These stencils, linked in a continuous chain, are attached to the jacquard loom, determining which yarns are lifted at each stage of the weaving process. Depending on the complexity of the pattern, a single design may require anywhere from a few hundred to several thousand Naksha Pattas, with more detailed motifs demanding a higher level of intricacy.

Selecting the Materials

Selecting the Materials

Selecting the Materials

The foundation of every exceptional Banarasi weave is the selection of premium raw materials. The finest silk yarns are sourced and carefully inspected to ensure their suitability for weaving. Banarasi brocades, in particular, require a specialized treatment process that enhances the silk’s luster and texture. The choice of zari—the metal

The foundation of every exceptional Banarasi weave is the selection of premium raw materials. The finest silk yarns are sourced and carefully inspected to ensure their suitability for weaving. Banarasi brocades, in particular, require a specialized treatment process that enhances the silk’s luster and texture. The choice of zari—the metallic thread woven into the fabric—also plays a crucial role in determining the final look and feel of the textile.

Preparing the Yarn

Selecting the Materials

The Weaving Process

Reeling

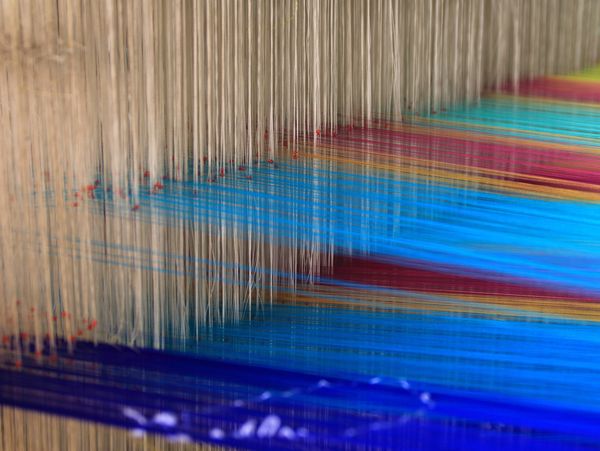

Before weaving can begin, the silk yarn undergoes a process known as reeling, where threads are carefully wound onto spools. The yarn for the warp (tana) is rolled onto a shuttle (dharki), while the weft (bana) is first mounted on a charkha before being transferred onto bobbins.

Dyeing

To achieve the desired color, the silk is dyed b

Reeling

Before weaving can begin, the silk yarn undergoes a process known as reeling, where threads are carefully wound onto spools. The yarn for the warp (tana) is rolled onto a shuttle (dharki), while the weft (bana) is first mounted on a charkha before being transferred onto bobbins.

Dyeing

To achieve the desired color, the silk is dyed by immersing the yarn in specialized dyeing tanks. The process requires precision to ensure uniformity in tone and richness in depth, bringing vibrancy to the final fabric.

The Weaving Process

Final Touches: Finishing & Packaging

The Weaving Process

Weaving is the most intricate and time-intensive stage of the process. Banarasi textiles are traditionally woven on jacquard pit looms, where the tana (warp threads) are stretched and lifted while the bana(weft threads) move back and forth through a shuttle. This careful interlacing of threads transforms raw silk into exquisite patterns, bringing the design to life.

Colour Matching & Iterations

Final Touches: Finishing & Packaging

Final Touches: Finishing & Packaging

A crucial aspect of weaving is the selection and balancing of colours - a step we refer to as "Meena-matching." Even after a pattern has been graphed and set up on the loom, colour combinations are tested through woven swatches. The design team and weavers collaborate closely, fine-tuning shades and placements through multiple iterations until the perfect balance is achieved.

Final Touches: Finishing & Packaging

Final Touches: Finishing & Packaging

Final Touches: Finishing & Packaging

Once weaving is complete, the fabric undergoes a meticulous finishing process. Any excess threads on the reverse side are manually trimmed, ensuring a clean and polished final piece. The sarees are then folded with care, preserving their delicate craftsmanship, and prepared for packaging.

Every Made in Banaras creation is a testament to th

Once weaving is complete, the fabric undergoes a meticulous finishing process. Any excess threads on the reverse side are manually trimmed, ensuring a clean and polished final piece. The sarees are then folded with care, preserving their delicate craftsmanship, and prepared for packaging.

Every Made in Banaras creation is a testament to the skill, patience, and dedication of our artisans—an embodiment of a weaving legacy that continues to inspire.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.